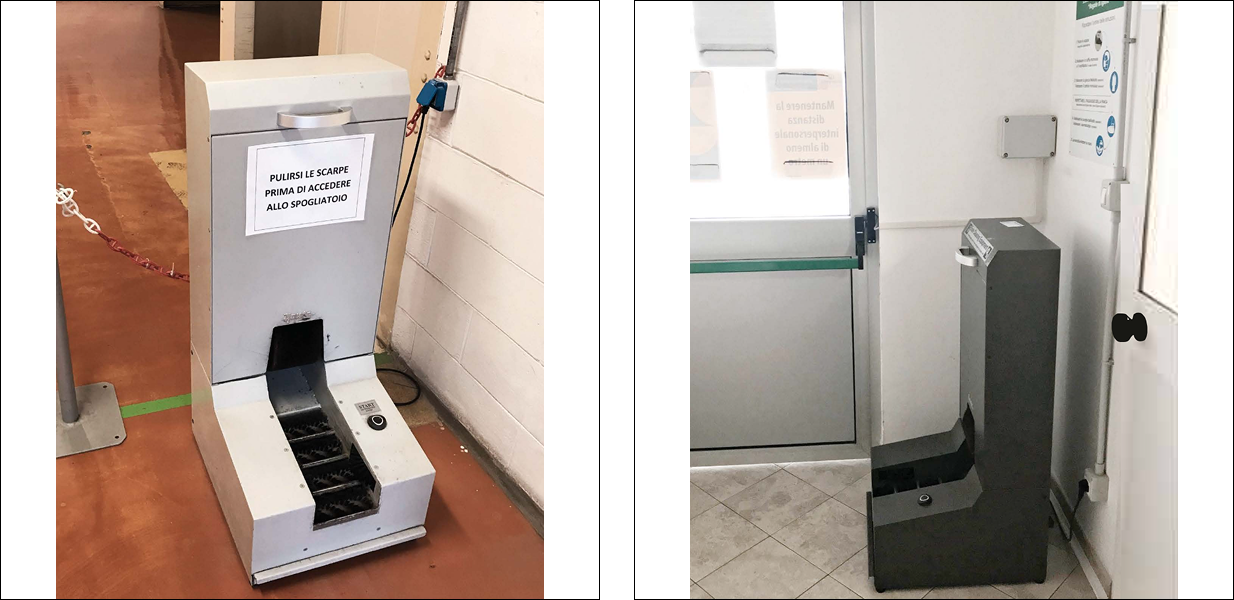

The HEUTE sole cleaner Solamat 100 used at Food Ingredients plants

Clean the shoes soles at every access in Food and Pharma Ingredients plants

Roquette Italia S.p.A., a subsidiary of the French family-owned company Roquette Frères, has been a prominent player in Italy's plant-based ingredients sector since its establishment in 1960. The company's production facility, located in Cassano Spinola, began operations in 1963 and has since become a cornerstone of the local economy, providing employment opportunities and contributing to regional development. Specializing in the processing of corn, Roquette Italia produces a diverse range of products, including starches, sugars, fibers, proteins, and oils, serving various industries such as food, pharmaceuticals, and bio-industrials. The facility operates continuously, processing approximately 2,000 tons of corn daily, and houses an internal applications development laboratory to foster innovation and meet evolving market demands.

In recent years, Roquette Italia has demonstrated robust financial performance, with a reported turnover of €595.35 million in 2022, reflecting a 36.67% increase from the previous year, and a net profit of €38.8 million. The company employs between 250 to 499 individuals, underscoring its role as a significant employer in the region. Emphasizing sustainability, Roquette Italia has invested in cogeneration plants to achieve energy autonomy and reduce environmental impact. In 2024, the company expanded its distribution network by appointing Rader SPA as the exclusive distributor for its core food ingredients throughout Italy, aiming to enhance service efficiency and market reach.

The challenge

Prevent contamination in production areas

- Location: Cassano Spinola

- Frequency of use: 3 shifts persons/ day

- Type of cleaning: dry

The solution

Clean the soles at every access with Solamat 100. The shoes cleaning machine Solamat 100 is designed for industrial applications. These types are equipped with four revolving brushes cleaning the soles and two lateral disk brushes do the same with the edges of the shoes. In addition, the upper leather brush cleans the upper shoe. Brushed off dirt falls into the large dirt collecting tray underneath the brushes. This tray can be easily emptied. The belt drive ensures tractive power and smooth running.

The benefits

The HEUTE Solamat 100 sole cleaner is an essential hygiene solution for food ingredient plants, ensuring contamination control and compliance with strict safety standards. In food production environments, even minor traces of dirt, dust, or external contaminants can compromise product integrity and lead to costly recalls or regulatory issues. The Solamat 100 effectively removes debris from employees' footwear using high-performance rotating brushes, preventing cross-contamination between different plant areas. Its automated operation ensures consistent cleaning without disrupting workflow, making it an efficient and user-friendly solution. By placing the Solamat 100 at every plant access point, facilities can significantly reduce the risk of foreign matter entering production zones, improving overall hygiene and food safety. Additionally, regular use of the system enhances workplace cleanliness, reducing the accumulation of dust and bacteria on floors.

Investing in this advanced sole cleaner not only helps maintain regulatory compliance but also reinforces a company’s commitment to high-quality food manufacturing and consumer safety.