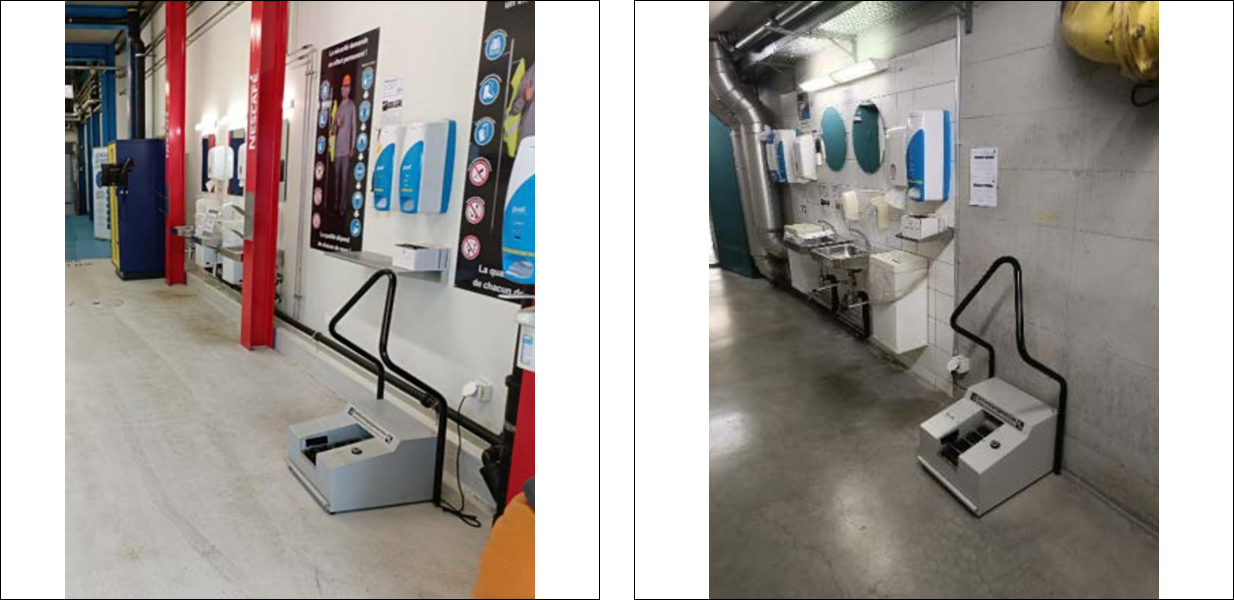

Using the HEUTE sole cleaner Solamat 90 in Coffee and Cereal plants

3 sole cleaning machines Solamat 90 placed in 3 entrances of the factory keeping more cleanliness

Nestlé Suisse SA, the Swiss subsidiary of the global food and beverage leader Nestlé, has been an integral part of Switzerland's economic and cultural landscape since its founding in 1866. Headquartered in Vevey, Nestlé Suisse SA operates nine production sites across the country, employing over 8,000 people. The company's diverse portfolio includes iconic global brands such as Nescafé, Nespresso, Maggi, and Purina, as well as cherished Swiss brands like Cailler, Thomy, Leisi, and Henniez. This blend of international and local products underscores Nestlé's commitment to delivering high-quality, innovative food and beverage options that cater to the tastes and preferences of Swiss consumers.

Beyond its commercial endeavors, Nestlé Suisse SA is deeply committed to research and development, housing five research institutes and five technology centers within Switzerland. As a founding partner of the Swiss Food and Nutrition Valley, the company plays a pivotal role in advancing food science and technology. Nestlé Suisse SA also places a strong emphasis on sustainability and social responsibility, actively engaging in initiatives that support environmental protection and community well-being. This dedication reflects Nestlé's broader mission to enhance quality of life and contribute to a healthier future for individuals and families in Switzerland and around the world.

The challenge

Needs of more cleanliness due to dirt dragging

- Location: 3 entrance of the factory in Orbe

- Frequency of use: 90 persons/ day

- Type of cleaning: dry

The solution

3 sole cleaning machines Solamat 90 placed in 3 entrances of the factory. The shoes cleaning machine Solamat 90 has four brushes, which counter-rotate and clean the soles from below. Two lateral disk brushes clean the edges of the soles. Brushed off dirt falls into the large dirt collecting tray. This tray can be easily emptied. The ergonomically shaped handrail provides the user with firm hold.

The benefits

Installing HEUTE sole cleaning machines at every entrance in coffee and cereal plants provides significant benefits by ensuring a high level of hygiene, preventing contamination, and maintaining product integrity. These plants handle raw ingredients that are highly susceptible to contamination from external dirt, dust, and microorganisms carried in on employees' footwear. HEUTE sole cleaning machines effectively remove debris using advanced rotating brushes and vacuum systems, minimizing the risk of cross-contamination between different production areas. This not only enhances food safety and helps plants comply with stringent hygiene regulations such as HACCP (Hazard Analysis and Critical Control Points) and Good Manufacturing Practices (GMP) but also improves operational efficiency by reducing the need for frequent floor cleaning. Additionally, maintaining a cleaner environment prolongs the lifespan of machinery and reduces maintenance costs caused by dust accumulation.

By integrating these machines at every entrance, coffee and cereal plants can safeguard their production processes, uphold quality standards, and ensure consumer safety.