Laboratory Particle Size Analyzer for Coffee

Know the particle size and shape of your coffee grounds for a perfect coffee taste

The reality

Across the world there are about 40 different known varieties of coffee beans which, in various blends and degrees of roasting, determine flavour, taste and brewing behaviour of the hot speciality. In addition to the selection of the green coffee, roast and blend, the grinding degree of the coffee powder is crucial for coffee preparation. If, for instance, you are preparing an espresso or Turkish coffee, a very fine grind with grain sizes below 1 mm is required; for common drip brewed and filtered coffee particle size is below 1.5 mm and for Scandinavian, French press or American brewed coffee it is just below 3 mm.

Inspired by capsule technology, the coffee industry is constantly bringing new types of coffee onto the market that continue to stimulate consumption. This increases the requirements for quality control, particularly with respect to the size distribution of coffee powder. Another challenge is the strong internationalisation of coffee producers, which makes comparability of analyses at different locations necessary. Industrial grinding of coffee and frequent changes in variety require a continuous, partially automated control of the particle size distribution to ensure consistent product quality.

The solution

Along with traditional sieving, laser diffraction is the most common method used for determining particle size distribution in coffee processing. Laser diffraction, in combination with RODOS dry dispersing, demonstrates its strengths in the quick and precise grain size analysis with HELOS in the laboratory as well as with MYTOS in the process.

The high sample throughput in RODOS dispersion means it is also possible to measure larger sample quantities of up to 100 g. This ensures high statistical significance and unrivalled repeatability and comparability of measurement results – including at different production sites. The fast measuring cycle and simple, automatic cleaning of the measuring section allow for up to 60 measurements per hour.

Recommended Sympatec Particle Size Analyzer configuration

Laser diffraction sensor HELOS/KR Multirange 0.5 - 3,500 μm with Dry Disperser RODOS/L and Precision vibratory feeder VIBRI/L

Measurement results Espresso and Mild

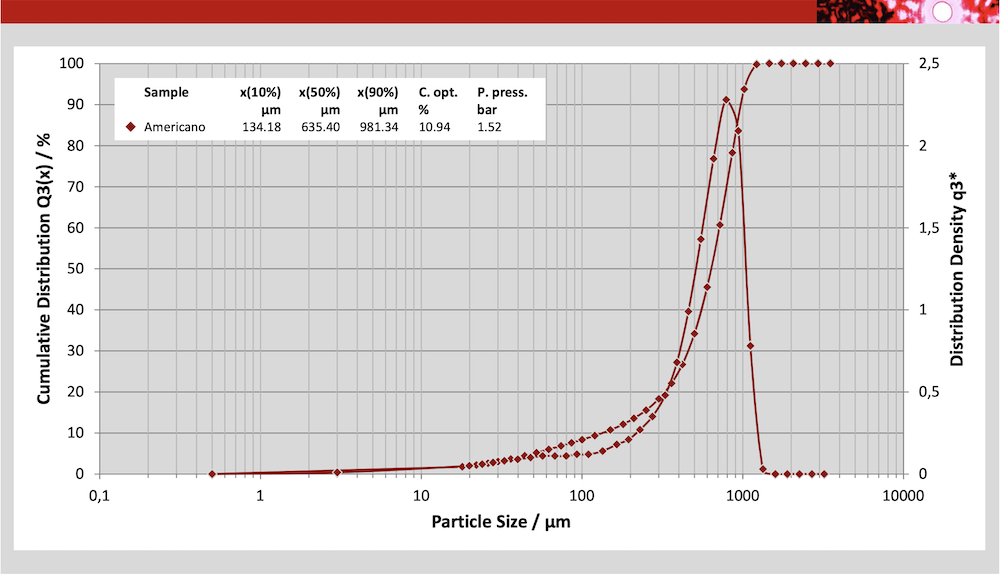

Measurement results Americano

The benefits

- Pure coffee of the highest quality

- Optimal production within specifications

- Precise and rapid control of particle size for consistent product quality

- Simple exchange of results between different locations

- Quick amortisation when eliminating screening

Controlling the particle size of coffee is of utmost importance in the coffee industry, and the Sympatec Particle Size Analyzer HELOS/KR with RODOS/L offers significant advantages in achieving this precision. With coffee being a beverage cherished for its flavor and aroma, the particle size plays a critical role in determining the extraction rate and overall sensory experience. By utilizing the Sympatec Analyzer, coffee producers can ensure consistent particle size distribution, resulting in optimal extraction during brewing. This translates to enhanced flavor profiles, increased aroma release, and improved consistency in each cup, thereby elevating the overall coffee drinking experience for consumers. Additionally, the ability to monitor and adjust particle size facilitates better control over the brewing process, leading to reduced waste and increased efficiency in coffee production.

The Sympatec Particle Size Analyzer HELOS/KR with RODOS/L empowers coffee manufacturers to create a delightful and consistent brew, meeting the discerning expectations of coffee enthusiasts and solidifying their position in the competitive coffee market.

Source:

https://www.sympatec.com/en/applications/coffee-particle-size-analysis/