Manual cleaning for Food production

Manual cleaning plays a key role in Food production environment and much more important when it comes to cleaning of complex equipment and stubborn dirt.

Why manual cleaning is important?

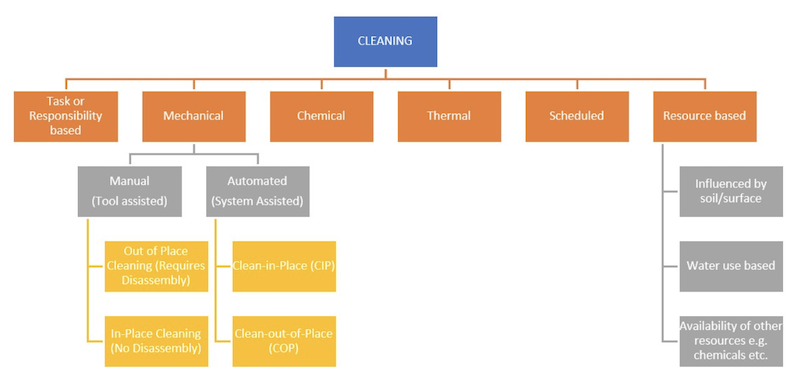

Industry cleaning methods may range from being process-specific (e.g., clean-in-place [CIP] for cleaning processing pipework and closed vessels) to the much simpler, process-agnostic manual cleaning involving the use of brushes, scrapers, squeegees, etc.

In contrast to manual cleaning, CIP normally involves the automated cleaning of equipment parts, such as the interior of pipes, vessels, or fittings without disassembly. This is generally done by pumping chemicals at a set concentration, temperature, and pH through the system, for a controlled period, at a flow rate that generates turbulence, which provides the mechanical action required as part of the cleaning process in a closed system. Clean-out-of-place (COP) involves disassembly and removal of parts to a remote automated cleaning system.

Once all the cleaning parameters used by these automated systems have been determined and programmed in, cleaning is as easy as pressing a button. However, the biggest limitation of CIP and COP cleaning is that the poor hygienic design of some equipment and surfaces, e.g., the presence of narrow, inaccessible spaces, or dead-end zones that allows contaminants to get trapped and be difficult to remove, doesn’t always allow for a thorough clean using the automated method.

If food equipment and surfaces aren’t cleaned properly, certain microorganisms may survive and persist by secreting a slimy, extracellular polymeric substance that can enmesh other organisms, nutrients, moisture, and foreign materials to form a biofilm that can firmly attach to a surface. According to Moorman and Jaykus (2019), manual cleaning is important for surface biofilm removal because “one just can’t sanitize one’s way out of a persistent biofilm problem within a facility. Biofilm eradication, therefore, generally requires equipment teardown, deep-cleaning and sanitation, and a follow-up verification.”

Proper cleaning of equipment and surfaces, therefore, is the first step toward better overall sanitation in food processing plants. Debra Smith, Vikan’s global hygiene specialist, clearly demonstrates the importance of manual cleaning action and the use of cleaning detergent and potable water to significantly reduce surface biofilm load rather than simply immersing a dirty piece in a chemical solution. Disinfection only follows appropriate cleaning and rinsing of the surface.

In a nutshell, applying detergents and disinfectants alone cannot make a fundamental difference in removing surface biofilms. Manual cleaning will always be required, in addition to other cleaning methods, because there will always be hard-to-reach places where biofilms can form and only be effectively removed through manual cleaning.

What is the proper manual cleaning?

Understand the concepts

Cleaning involves the removal of visible debris from a surface. Industry best practices and regulatory requirements have always been to clean before you disinfect the surface.

Cleaning should not be taken as a one-size-fits-all activity, since several factors may influence how, when and why to remove soils from a surface. The cleaning activity may be achieved in many ways, and a single cleaning method may involve overlaps of various cleaning activities:

As shown, manual cleaning may or may not involve the disassembly of the parts of equipment. Moreover, it is important to define the ‘level of clean’, which is a risk-based decision generally dependent on the type of contaminant (mainly microorganisms, allergens, and foreign material) to be removed from a surface. Some of the factors influencing the level of clean are as follows:

- Whether the contaminant/hazard present is required to be eliminated or minimised to an acceptable level through the cleaning process.

- Whether the cleaning activity itself should minimise the spread of the contaminant.

- Whether the cleaning activity will have a negative impact on the surface being cleaned.

- Whether the prevailing regulations, standards, and best practices will be met through the cleaning activity.

Minimise the spread of contamination during cleaning

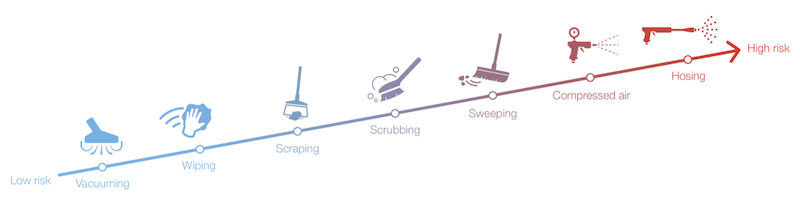

As shown below, certain cleaning activities may increase the risk of contamination spread, hence they are deemed high-risk.

As illustrated, use of high pressure cleaning techniques, is a high-risk activity compared to wiping or scraping. The former will generate liquid aerosols and droplets, or particles, that will spread over a considerable distance, carrying with them contamination from the surface being cleaned. However, other common manual cleaning techniques, like scrubbing, or sweeping, are generally classed as medium risk, requiring some caution in their performance. For instance, scrubbing dirty parts using a brush is better done by submerging the part under the water while scrubbing, to minimise the spread of droplets generated by the scrubbing action.

Select the right tool for the right job

The selection of manual tools is vital, since this can greatly influence its cleaning efficacy and durability, and its subsequent cleaning maintenance and storage. Some useful tips on tool selection are provided below:

- Choose the right bristle type for brushes and brooms. Stiff bristled brushes are good for removing stubborn debris, with or without the use of water, but may damage surfaces, while very soft bristled brushes may be ineffective in removing rigid soils from surfaces but are good for sweeping up fine powders.

- It is best to use total-colour tools that are easily identifiable, by use or hygienic zone. Segregation of tools in this way goes a long way in reducing cross-contamination in food plants.

- Where higher temperatures are encountered in operations, use tools capable of withstanding high temperatures.

- Evaluate whether special application tools will be required, say, for conducting deep cleaning, detailed cleaning, or high- or low-level cleaning.

- Hygienically designed tools normally have smooth surfaces, rounded edges, and no crevices where contaminants can accumulate and be difficult to remove. Vikan’s UST brushes and Ultra-Hygiene range of handles and squeegees are great options for hygienic tools to use for food manufacturing facilities processing high-risk products.

Source :

https://www.vikan.com/int/services/vikan-blog/abc-s-of-manual-cleaning-part-i-why-is-it-important/