Sympatec Particle Size Analyzer for Cement

HELOS and RODOS - a good combination of Sympatec Laser Diffraction Sensor and Dry Dispersing System to control quality of Cement and Raw Meal at any cement plant laboratory.

The reality

Industrial, business or residential buildings, arenas, traffic routes or infrastructure projects – contemporary architecture with its modern buildings is unimaginable without cement-bound materials. As a versatile and permanent binder for concrete, plaster, mortar or screed, cement is one of the most important and mostly used building materials worldwide. By addition of water, cement turns into cement paste, which hardens through hydration to durable cement stone. The cement industry faces challenges such as assurance of consistent, grade-specific quality and furthermore energy and resource efficiency.

Why do a cement plant need a Particle Size Analyzer?

- Optimization of process control through prompt monitoring of grinding fineness of raw meal and cement

- Faster availability of results for quality and process control

- Assurance of a consistently high product quality

- Reduction of energy consumption by avoiding overgrinding

- Maximum utilization of raw materials

- Decrease of out-of-spec material during type changes

- User-independent, fast and reliable measuring results

- Outstanding reproducibility of measuring results and comparability of system-to-system or location-to-location

The solution

While traditional procedures of fineness measurements, like sieving or the determination of cement powder’s specific surface using the Blaine-device, only deliver single values after time-consuming analyses, laser diffraction analysis evaluates the entire grain size distribution in high resolution without operator influence. The grinding grade, too high or too varying fine content (< 2 µm) or coarse content are detected reliably and promptly. With a powerful dry dispersion, laser diffraction offers an unrivalled sensitivity and high reproducibility over the entire cement particle size range with user-independent measurements in a matter of seconds.

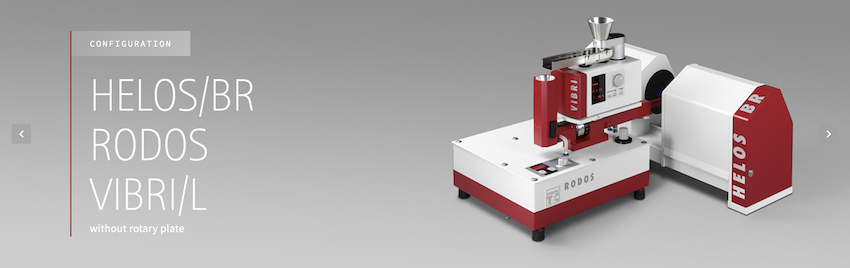

Recommended Sympatec Particle Size Analyzer configuration

Laser diffraction sensor HELOS/BR Multirange 0.1 - 875μm with Dry Disperser RODOS and Precision vibratory feeder VIBRI/L

HELOS/BR - The most simple version of the Sympatec HELOS Laser Diffraction Sensors and finds room on every laboratory table. It integrates up to 5 optical modules for a measuring range from below 0.1 µm to 875 µm. A multitude of measuring tasks are fulfilled reliably and offers measuring confidence even to the coarser particle range. The laser analyzer can be used with all HELOS dispersing units. RODOS - Dry dispersing unit with compressed air and particle accelerations of up to 100 m/s, achieves unique dispersion performance for powder, fibres and granulates, ranging from under 0.1 um to 4,000 um. Sample quantities of under 1 mg to 1,500 g are reliably and reproducibly dispersed. Statistically significant analyses are achievable with sample volumes of up to 1,000 ml, even with widely distributed particle systems. The accelerated individual particles are supplied to the HELOS laser diffraction or QICPIC image analysis measurement zone in the aerosol open jet, and precisely measured. VIBRI - Precise dosing and supply of particle system from miligram to kilogram with contant sample mass-flow.

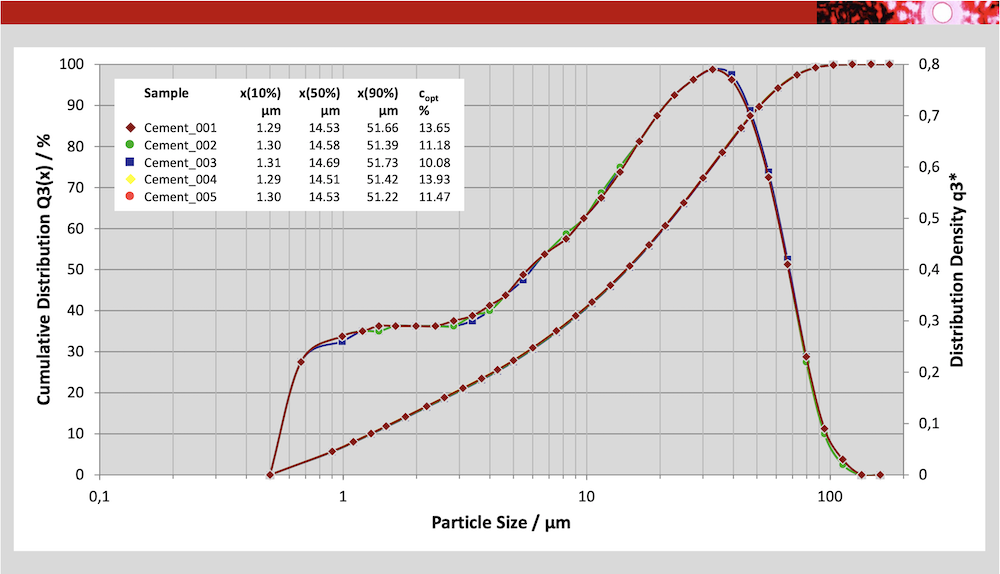

Cement | 5 repetitions

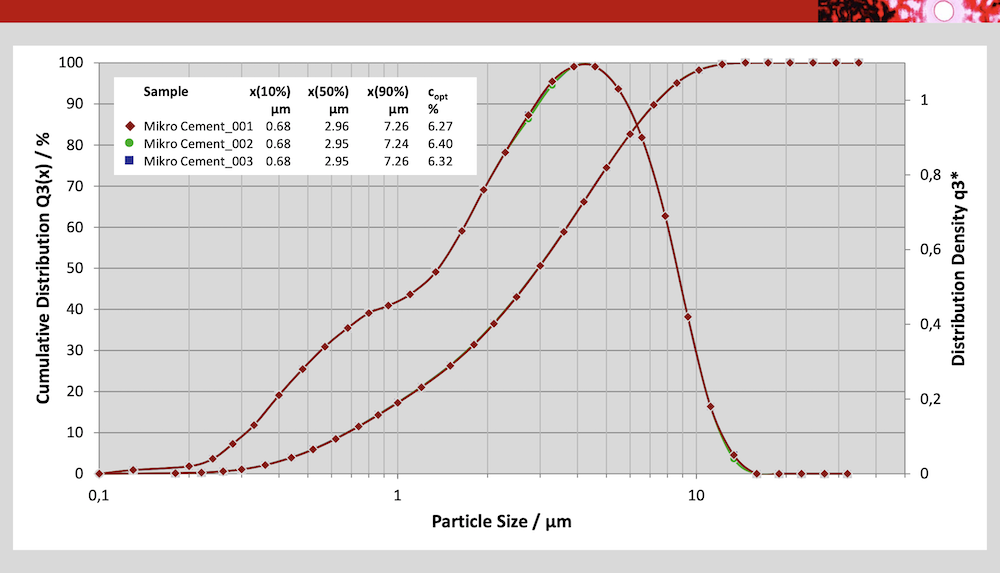

Micro cement | 3 repetitions

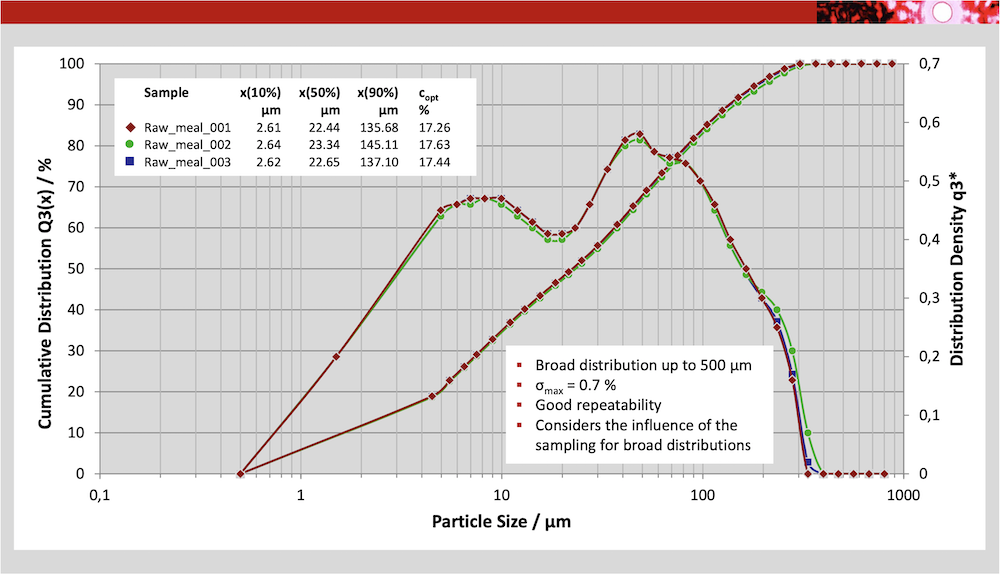

Raw meal | 3 Repetitions

The Benefits

Precise and fast control of the particle size distribution guarantees for

- Consistent product quality

- Optimum process operation by continuous control of fineness for cement and raw meal

- Maximum yield from raw materials

- Reduction of energy consumption

In the cement production industry, the Sympatec Particle Size Analyzer HELOS/BR and RODOS, play a crucial role in determining product properties. The accurate assessment of particle size distribution in cement is paramount as it directly impacts the material's performance and final product quality. By employing these advanced analytical tools, cement manufacturers can gain valuable insights into the particle size distribution, ensuring a well-controlled and consistent cement product. This information aids in optimizing the manufacturing process, enabling the production of cement with precise and desired characteristics such as setting time, strength, workability, and durability. Moreover, the Sympatec Particle Size Analyzer facilitates the exploration of different cement formulations and additives, leading to the development of innovative and high-performance cement products that cater to specific construction requirements.

Ultimately, utilizing the Sympatec Particle Size Analyzer enhances overall cement quality, reduces material waste, and strengthens the competitiveness of cement manufacturers in the global market.

Source:

https://www.sympatec.com/en/applications/cement-particle-size-analysis/