Sympatec Particle Size Analyzer for Chocolate

Using particle size analysis to control the production and quality of chocolate

The reality

Chocolate is a highly popular food all over the world and consists mainly of cocoa and sugar. Recipes with cocoa butter, dairy products, nuts, spices and aromas provide greater product variety. Chocolate, as a luxury food, is subject to cultural preferences and is produced in regionally varying qualities that are influenced by the sensory sensitivity of the tongue. While people in Japan prefer very fine and smooth chocolate with an average particle size of around 10 microns, people in Europe like chocolate with an average particle size of 12 microns to 25 microns. 30 microns or more are common in American chocolate. The most chocolate is consumed in Europe and North America. The per capita consumption in some Northern and Central European countries is above 8 kg, while Switzerland is the worldwide leader at more than 10 kg. Chocolate is marketed directly at consumers and as an industrially processed semi-finished product.

The industrial production of high-quality chocolate is carried out in a technically demanding process. Cocoa beans from various tropical provenances are used as the raw material for chocolate production. After cleaning, roasting, sterilising and peeling, the cocoa beans are ground into a viscous mass – the cocoa mass. The cocoa mass is then pressed so that the cocoa butter separates from the dry cocoa mass. The fat is then removed from the dry cocoa mass to a greater or less extent and is then available as a cocoa powder with typical residual fat content between 10% and 20% as an intermediate or final product. The cocoa butter is mainly used as an ingredient in chocolate production. The original cocoa mass is sometimes directly used for chocolate bars.

Very different particle sizes are found in the quality and production control depending on the process stage. The particle sizes range from over 300 microns during pre-rolling to below 30 microns in the final products. The industrial manufacturing process requires a continuous control of the particle size distribution to ensure consistent product quality – both in continuous and in batch production, and particularly at different production sites.

The solution

Typical Sympatec Particle Size Analyzer configuration

Laser diffraction sensor HELOS/BR Multirange 0.1 - 875μm with Wet Disperser QUIXEL and Liquid Treatment Unit LIQUIBACK

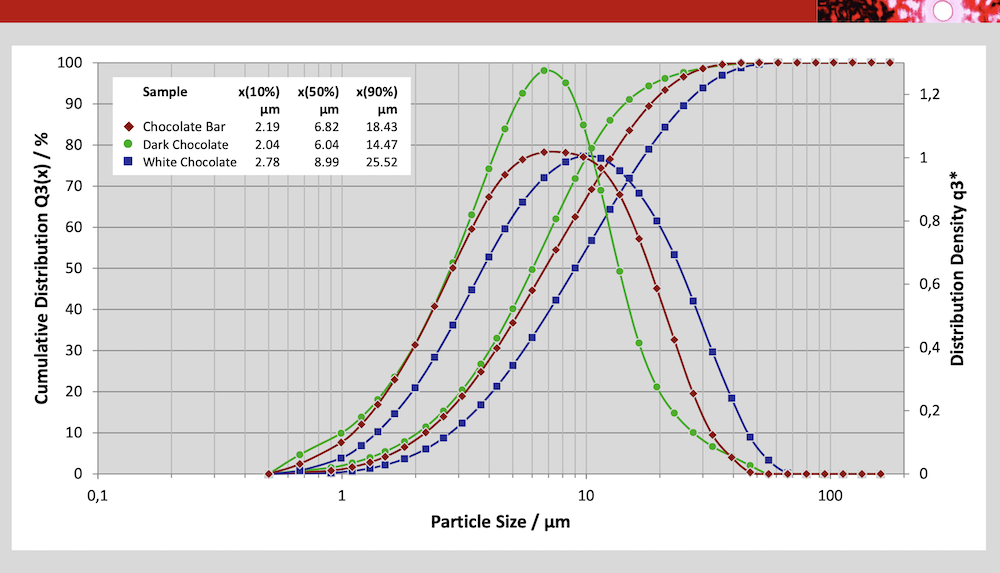

Measuring results | three types of Chocolate

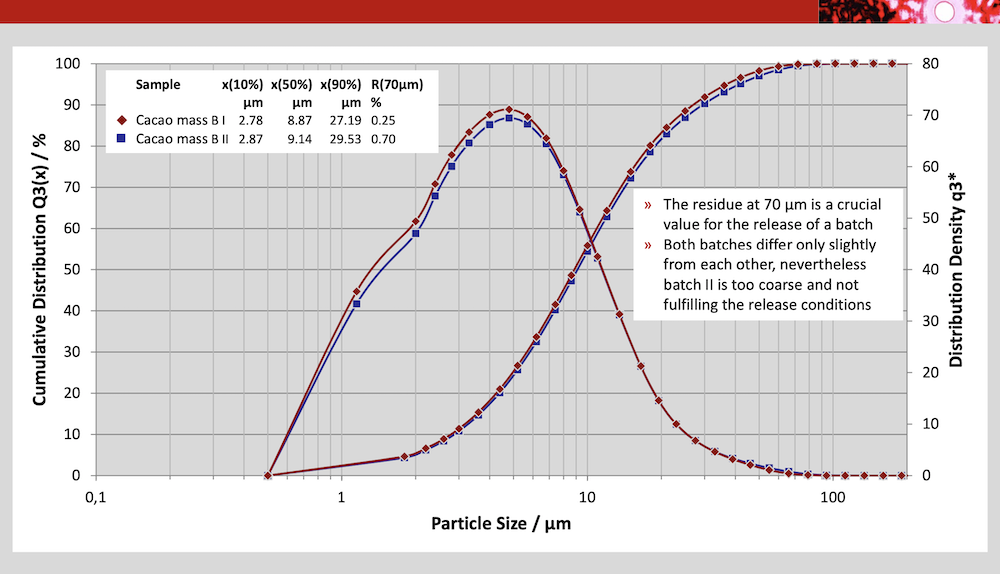

Measuring results | two batches of Cacao Mass

The benefits

- Efficient production and best quality of final product

- Ensuring consistent product quality in various production locations

- Fast, accurate and high-resolution particle size analyses

- Transferable standard measurement methods

- Automated measurement routines

- Stable measurement technology with high availability

- Measurement of optimally tempered samples in organic dispersing media | Sunflower oil, palm oil, liquid cocoa butter, Isopar G

The Sympatec Particle Size Analyzer HELOS/BR, combined with the Wet Dispersing System QUIXEL, offers significant advantages in controlling the particle size of chocolate in both laboratory and production settings. Precise particle size measurement is essential for achieving optimal texture, mouthfeel, and overall quality of chocolate products. The HELOS/BR ensures high-resolution laser diffraction analysis, providing accurate and reproducible results, while the QUIXEL system enables effective dispersion of chocolate samples in liquid media, preventing agglomeration and ensuring reliable measurements. This combination allows manufacturers to monitor and optimize refining and conching processes, ensuring consistent particle size distribution that enhances product quality and consumer satisfaction. Additionally, real-time analysis reduces the need for excessive trial-and-error, increasing efficiency and reducing production costs.

By implementing these advanced technologies, chocolate producers can maintain stringent quality standards, improve process control, and enhance the overall sensory attributes of their final products, ensuring superior consistency from batch to batch.

Source: