Vikan cleaning tools for Confectionary Processing plant

Whether you are a budding Willy Wonka or a global manufacturer of quality confectionary Vikan can help maintain the quality and safety of your products.

The obvious solution to removal of sticky, sugary, high fat, and hard-set confectionary deposits would be to use hot water, detergents, and manual and/or CIP cleaning. However, if melted chocolate comes into contact with even a small amount of moisture its texture can change, causing it to seize or thicken and become unusable.

Consequently, for many years, chocolate manufacturers have minimised the use of water in their cleaning regimes. Additionally, the introduction of water to a production environment will aid the growth and spread of microbes, including harmful bacteria like Salmonella. Previously, the high sugar and fat content, and low water activity (Aw)of sugar confectionary was thought to minimise its microbial food safety risk.

However, over the last 15 years, high profile cases involving the contamination of chocolate with Salmonella, and our improved understanding of how Salmonella can survive in low Aw foods, has impacted significantly on this product sector.

Vikan are specialists in cleaning so whether you wet clean, dry clean, use controlled wet cleaning, or any combination of these, we can provide the comprehensive range of products and advice to help.

Selecting the right cleaning tools

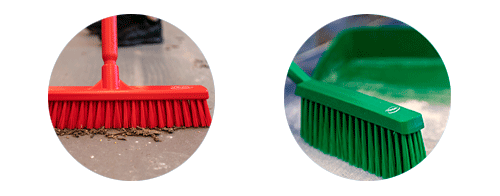

Brushware

- Fine bristle brushes tend to clog quickly and be difficult and time consuming to clean when used with fine dry powders like cocoa, icing sugar, starches, and gelatine.

- Choose medium bristle brushes to clean up larger loose dry soils like granulated sugar, cocoa beans and nibs, dried fruit and nuts, chocolate chips etc.

- Choose stiff bristled brushes to remove sticky, sugary and fatty deposits as part of a controlled wet clean.

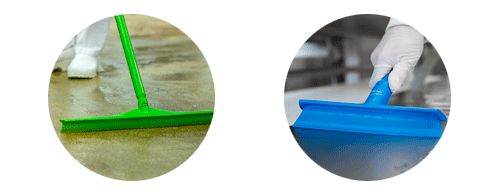

Squeegees

- A fully moulded, single-bladed squeegee is a great alternative to the use of a fine bristle brush for removal of fine dry powders like cocoa, icing sugar, starches and gelatine. They don’t clog and are much easier and faster to clean.

- They also work well for cleaning surfaces of molten confectionary.

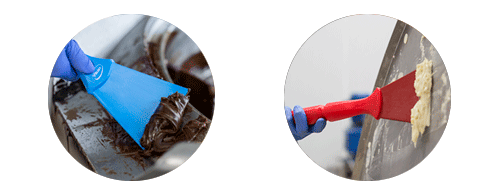

Scrapers

Scrapers are an effective way of removing set, and semi-liquid sugar confectionary from surfaces. Take care to choose a scraper blade material that effectively removes the soil but doesn’t damage the surface being cleaned.

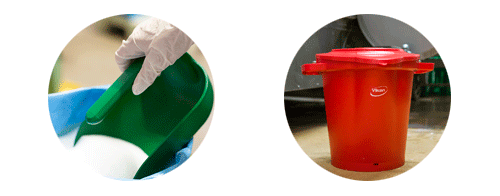

Dedicated colours

Use equipment of a dedicated colour to minimise the risk of cross-contamination. For example,

- Orange for products that contain gelatine

- Green for those that are gelatine-free

Products handling tools

Shovels, scoops, jugs, stirrers, and buckets should be made of food contact compliant materials and preferably be of a contrasting colour to the food to aid visual detection in the food.

Suggested Products for Confectionary processing plants

The confectionary sector requires strict adherence to sanitation rules and regulations. Tools from Vikan are made out of tough, compliant materials such as polypropylene and stainless steel. Unlike foamed plastic or wooden tools, Vikan high-quality products have smooth surfaces for easy clean-up and better hygiene. Vikan tools are hygienically designed, which makes them easier to clean and less likely to harbor bacteria.

Vikan tools come in up to twelve colours, making them ideal for integration with colour-coded plans. Colour-coding helps prevent cross-contamination between raw and finished products, as well as keeping allergens separated.

Regardless of your operation’s size and complexity, Vikan has the tools and expertise to help you execute your colour-coding plans.

Source:

https://www.vikan.com/int/sectors/food-beverage-processing/confectionary-processing