Usage of cleaning tools compliant with 5S

Below herewith are some practices of using cleaning tools following 5S in food industry.

Introduction to 5S

5S has been shown to be an effective Japanese-based model for increasing operational efficiency along with improving food safety and quality in food processing plants. The main goal of 5S is to help companies create safe, neat, clean, and structured workplaces with reduced waste. Because over 85 percent of food safety issues in a site are generally caused by failures in Good Manufacturing Practices (GMPs) rather than Hazard Analysis and Critical Control Points plan shortcomings, 5S has gained prominence industry-wide as a way to comply with Food Safety Modernization Act-based regulations that focus on prevention.

5S stands for :

- Seiri - Sort : “Everything has a purpose” Select what’s needed for the job and remove everything else from the work area.

- Seiton - Set in order : “Everything has its place” Arrange items so that they are easy to select, use, and return to their proper location.

- Seiso - Shine : “Everything is clean and well-maintained” Spot dirty, non-conforming items and then clean, repair, or remove them from service.

- Seiketsu - Standardize : “Every action is well-known and clearly stated” Develop and implement visual standards that employees are able to consistently follow.

- Shitsuke - Sustain : “Every action is replicated and improved upon” Create an improvement culture among employees so they can find better ways of reducing efforts.

Benefits of 5S to Food industry

- Supports company-wide integration of work processes through the participation of all employees

- Creates a stable foundation for the systematic implementation of lean manufacturing practices that are required to reduce wastes and inconsistencies, and thus promotes value-added work

- Raises employee morale and motivation through hands-on participation

- Streamlines processes and reduces operating costs

- Engages employees with helping to create a safer and more sustainable workplace

Tips of using cleaning tools compliant with 5S

Color-coding program implementation - Colour-coding promotes the idea of a “visual factory” that makes it easy for any employee to find the right tool at the right time. This can minimise the risk of product cross-contamination, for example, by having a different tool colour for those used in contact with food and food contact surfaces and those used to clean floors and drains.

Proper Storage of Cleaning Tools - Wall brackets and shadow boards are an essential component of an effective and hygienic tool management program. Effective (colour-coded) storage of cleaning tools can help ensure that tools are always in the right place at the right time, reducing labour costs. Tool storage systems can also prevent tools from being stored on the floor where they are more likely to become contaminated, damaged, or pose a trip hazard.

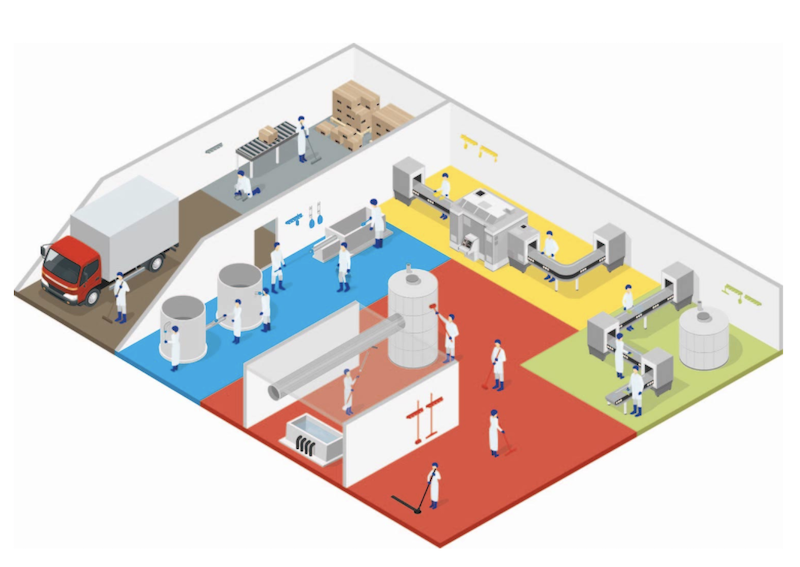

Hygienic Zone Planing - A zone plan will provide an overview of your site, divided into different coloured zones, dependent on your requirements. It will also provide you with lists of which tools are used where, and the ability to print this information for use in audits. Zone plans help employees take ownership of the tools in their zone by helping them ensure that only the allocated tools are used.

Use Hygienic Deisgn Cleaning Tools - Food facilities that have hygiene critical / high risk areas (where foods are processed, packed, or ready-to-eat foods are manufactured) should consider investing in hygienically designed facility fixtures, equipment, and tools, which are easier to clean, disinfect, and maintain, than their conventional counterparts.

Cleaning, disinfection and maintenance - Regular cleaning, disinfection, and maintenance of all equipment and surfaces, as appropriate, is a critical part of Shine and Sustain within 5S. This includes the cleaning, disinfection, and maintenance of cleaning tools, which should be conducted at a level and frequency, as determined through risk assessment, to ensure the maintenance of a hygienic production environment.