ProfilGate® tire and sole cleaning in new factories

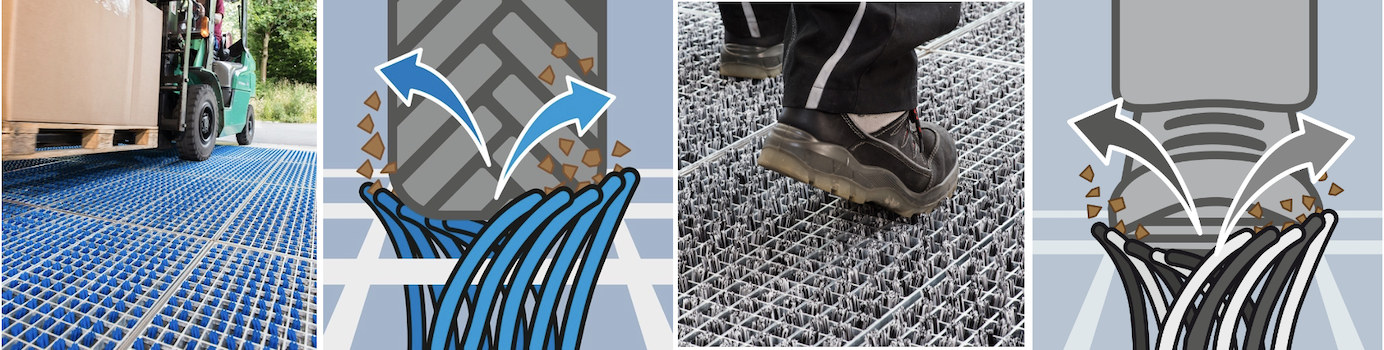

The planning and installation of ProfilGate tire and sole cleaning systems in new factories helps customers to set up the hygiene concept at the beginning and save cost.

In recent years, there has been a significant surge in the establishment of new factories worldwide. This trend can be attributed to various factors, including advances in technology, globalization, and growing consumer demand. With the emergence of innovative manufacturing processes, these factories are able to boost production efficiency while minimizing environmental impact.

Why to consider ProfilGate at your new factory?

For those who are setting the new factory, remember one thing that is your new factory should last for the next decades. High cleanliness is more important then ever before. Professional recommendations for a strategic positioning of ProfilGate in your basic logistics concept by our ProfilGate experts. Lower installation costs, as the pit can be considered during construction phase (no need to dig into the ground). And last but not least, there are some advantage once applying ProfilGate installations at your new factory:

- Higher quality of your products

- Less customer complaints

- Less cleaning costs

- Longer durability of your floors and lower refurbishing costs

- Improved health and safety for your employees

The preparation

Step 1 - planning

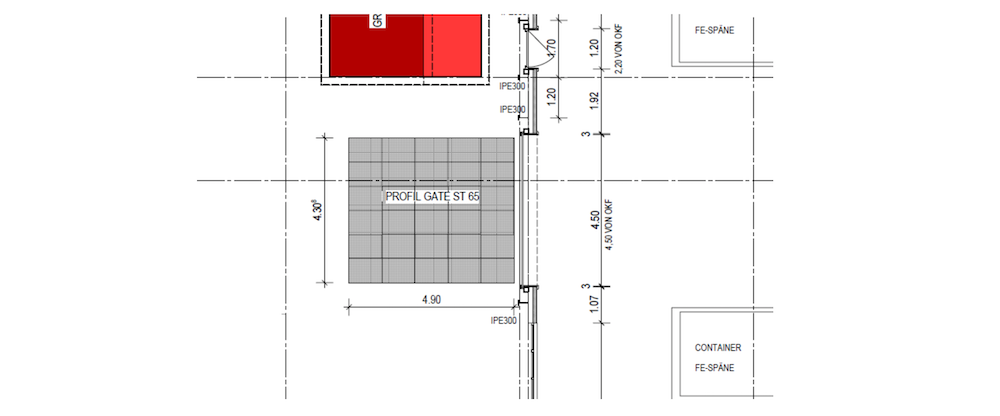

Based on the architect's drawing, we can make recommendations where ProfilGate should best be installed. Please share your architect's drawing with us, so we can provide our best possible support. If you have concerns about confidentiality, we can sign a “non-disclosure agreement”.

Step 2 - Proposal

After receipt of the architect's drawing we make our proposals by adding ProfilGate in your drawing and prepare the corresponding quotation. In this example 5 segments in length and 6 segments in width were considered. The dimensions are to be seen in the drawing, so it ́s easy to understand!

Step 3 - Leaving the pit

When you decide to install ProfilGate in your new building, the pit for the system can be considered directly from the beginning:

- Cost saving

- No need to dig the pit in the new flooring

- ProfilGate can work from day one of your new operations

Step 4 - Covering

To avoid damages of the pit and to make the area accessible to vehicles during that phase, wooden boards can be placed in the pit

Step 5 - In operation

When the construction is finished, the trays, grates and brushes can be placed in the existing pit and operation of the new facility can start.

The conclusion

Implementing the ProfilGate Tire and Sole cleaning system in new factories offers several advantages and cost-saving benefits. Firstly, by proactively preparing for the system's integration during the factory's initial construction phase, companies can seamlessly incorporate the required infrastructure, reducing installation complexities and potential disruptions to operations later on. Moreover, this proactive approach enables a more efficient allocation of resources, ensuring that adequate space and utilities are readily available. In terms of cost savings, early preparation prevents costly retrofits and modifications in the future, optimizing the overall budget allocation for the factory project. Additionally, the ProfilGate system's superior cleaning capabilities help maintain a cleaner and safer working environment, reducing maintenance costs and prolonging the lifespan of machinery and equipment.

Ultimately, investing in advanced preparation for the ProfilGate Tire and Sole cleaning system sets a solid foundation for enhanced productivity, longevity, and cost-efficiency in the new factory's operations.