ProfilGate® tire and sole cleaning at Plastic & Packaging plants

Dust control is crucial in the plastics and packaging industry to maintain product integrity, prevent contamination, and ensure worker safety.

The plastics and packaging industry holds immense importance in today's world. It serves as a backbone for various sectors by providing essential materials and solutions. Plastics, with their versatility and durability, enable the creation of innovative products and packaging that ensure the safety, preservation, and convenient delivery of goods. The industry plays a vital role in protecting perishable items, reducing food waste, and extending shelf life.

Dust control is of utmost importance in the plastics and packaging industry. The production and handling of plastic materials and packaging often generate significant amounts of airborne dust particles. These dust particles can lead to various issues such as product contamination, compromised product quality, equipment malfunction, and safety hazards for workers.

ProfilGate® – Solution for the Clean Driving and Walking Zone

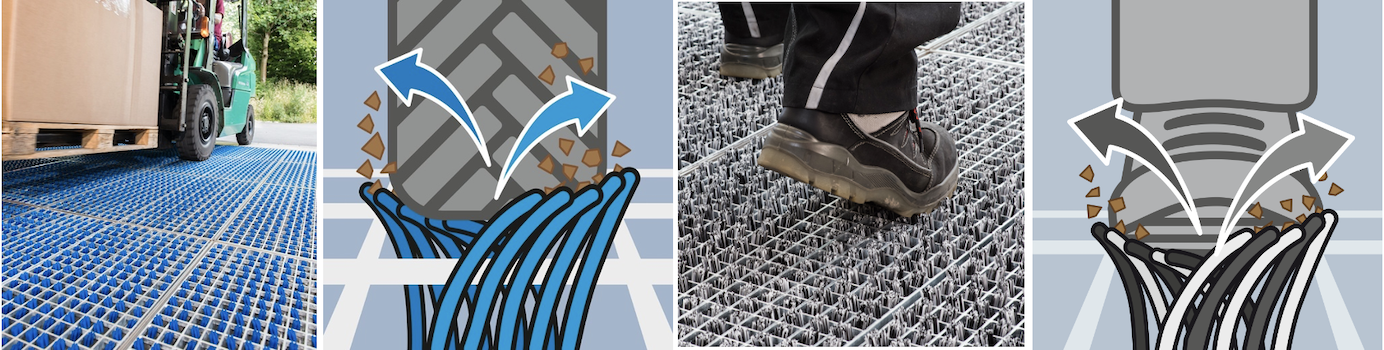

No matter if you unload from a dirty delivery truck or take dirt inside your facility via material handling devices – most receiving areas build up dirt, debris and dust from tires and wheels. The next set of transport vehicles takes the dirt further and deeper into your storage and production areas till it causes issues inside your facilities. By strategically placing ProfilGate® throughout your building, you can now capture up to 80% of dirt – which is otherwise attached to your wheels, casters and tires – before it migrates and enters your production facility.

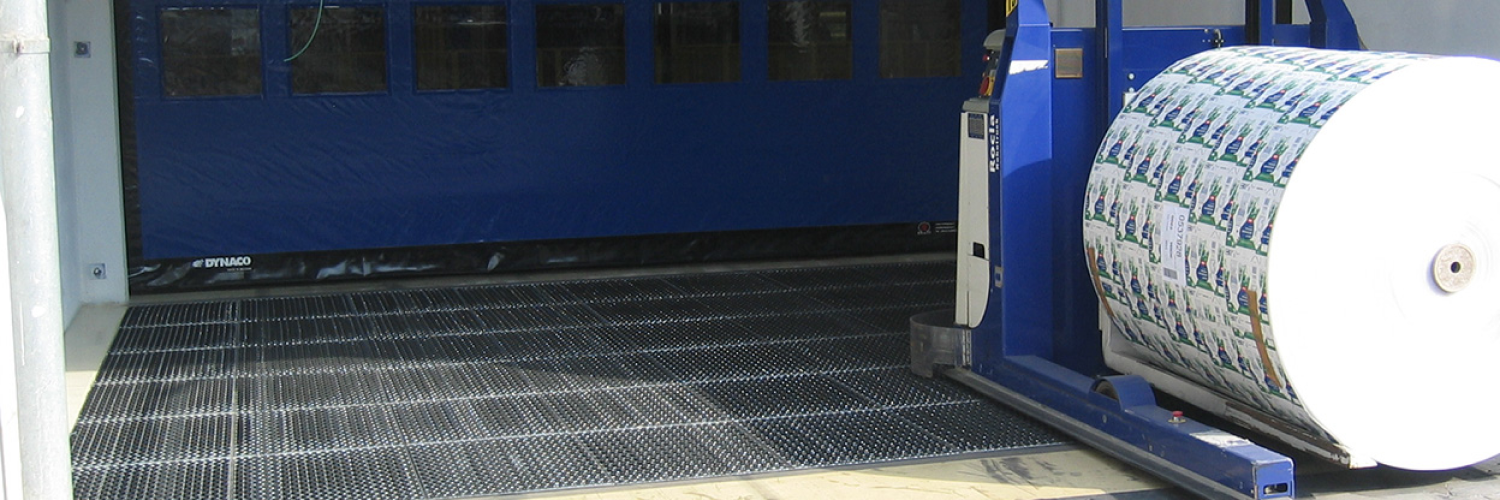

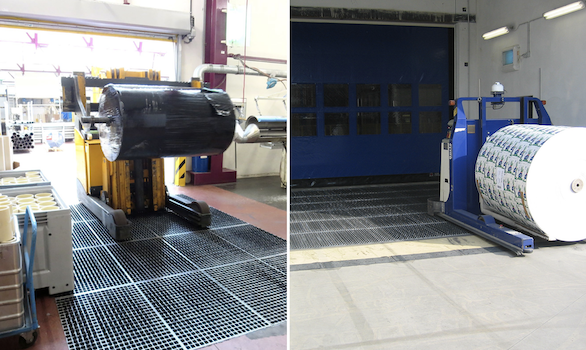

The installation of ProfilGate at some areas in Plastics and Packaging plants

Forklift (left picture) and AGV (right picture) are driving into production area in Packaging plants

Huhtamaki is a global packaging solutions company with a rich history spanning over 100 years. Headquartered in Finland, Huhtamaki operates in over 35 countries and employs approximately 18,600 people worldwide. The company specializes in providing sustainable packaging solutions across a wide range of industries, including foodservice, food and beverage, healthcare, and personal care.

Huhtamaki's diverse product portfolio includes paper-based, molded fiber, and plastic packaging, catering to the evolving needs of customers and consumers. With a strong commitment to sustainability, Huhtamaki focuses on developing eco-friendly packaging options and has set ambitious sustainability goals to reduce waste, promote recycling, and minimize environmental impact. Through innovation, customer-centric approach, and global presence, Huhtamaki continues to be a key player in the global packaging industry.

Tetra Pak is a renowned global company specializing in food processing and packaging solutions. With its headquarters in Switzerland, Tetra Pak operates in more than 160 countries and employs over 25,000 people worldwide. The company is known for its iconic carton packaging solutions, particularly in the food and beverage industry.

Tetra Pak's packaging systems are designed to ensure product safety, quality, and extended shelf life while minimizing environmental impact. They offer a range of solutions, including packaging materials, processing equipment, and technical services. Tetra Pak emphasizes sustainability and has set ambitious goals to create packaging that is fully recyclable and sourced from renewable materials. With a focus on innovation, customer satisfaction, and sustainable practices, Tetra Pak continues to shape the global packaging industry and drive positive change in the way we package and consume food and beverages.

The conclusion

Investing in a system like ProfilGate is essential for Plastics and Packaging plants. These industries often face challenges related to dust, dirt, and debris that can accumulate within production facilities. The ProfilGate system offers a comprehensive solution by effectively removing dirt and particles from the wheels and soles of vehicles and footwear as they pass over the specialized grates.

By implementing ProfilGate, plants can significantly reduce the ingress of contaminants into the production area, ensuring a cleaner and more hygienic environment. This, in turn, helps to maintain product quality, prevent cross-contamination, and minimize equipment breakdowns caused by dust and debris. The investment in ProfilGate not only improves overall operational efficiency but also demonstrates a commitment to maintaining high standards of cleanliness, safety, and product integrity within the Plastics and Packaging plant.