Vikan cleaning tools for Dairy Processing plant

Whether you are a boutique cheese maker or a large International dairy processor Vikan can help maintain your product quality and safety.

Vikan knows that most dairy products fall into the chilled, ‘Ready-to-eat’ (RTE) product category. They also included dry milk powder production, used as an ingredient in many other products, and as a base for infant formula. Microbiologically, chilled RTE products and infant formula production are classed as high-risk. Consequently, producers of these products in particular need to maintain high levels of hygiene to ensure consumer safety, longer product shelf-life, and brand reputation.

Dairy processors face additional challenges associated with the production of modified dairy products, to cater for vegans, vegetarians, lactose intolerant consumers etc., where control of product cross-contamination (including allergens) is essential in compliance of legal and labelling requirements.

Additionally, health-driven pressures to reduce the levels of salt, fat, sugar and preservatives in many products, including dairy products, has created both product safety and quality challenges due to the removal of these traditional product safety/spoilage ‘hurdles’.

The impact of all of these challenges can be significantly reduced through the maintenance of high levels of environmental and equipment hygiene and Vikan's tools and experts are here to help.

Selecting the right cleaning tools

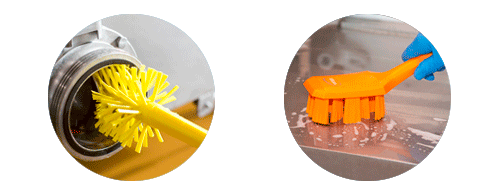

Brushware

- Choose stiff bristled brushes for removal of dried on dairy product. Use the brush on its own (dry cleaning), or in combination with water, detergent/sanitiser (wet cleaning).

- Choose medium bristled brushes for removal of wet semi-solid soils, e.g., curd solids.

- Choose a soft bristled brush for removal of loose dry soils, e.g., dried milk powder.

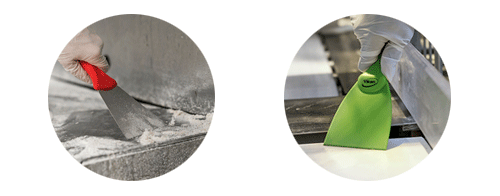

Squeegees

Choose a squeegee that is appropriately effective, hygienically designed, and durable e.g.

- foam bladed squeegees are highly effective at removing liquids like milk or whey from surfaces, but the blades are difficult to clean and disinfect and wear quickly.

- a fully-moulded, single-bladed squeegee is easy to clean and disinfect; is more durable; and may be better than a brush for removal of loose wet soils, like cheese curds, and powders like dried milk, as it doesn’t clog.

Scrapers

Choose scrapers that effectively remove the soil but don’t damage the surface.

Metal blade scrapers may scratch metal or plastic surfaces making the surface more difficult to clean and increasing foreign body risk.

Dedicated colours

Use equipment of a dedicated colour for a dedicated task, for example,

- Green for products that contain lactose, and Pink for those that are lactose-free.

- Red for raw-milk production areas, and Yellow for processed product areas.

Product handling tools

Shovels, scoops, jugs and buckets should be made of appropriately product contact compliant material.

Suggested Products for Dairy processing plants

The dairy sector requires strict adherence to sanitation rules and regulations. Tools from Vikan are made out of tough, compliant materials such as polypropylene and stainless steel. Unlike foamed plastic or wooden tools, Vikan high-quality products have smooth surfaces for easy clean-up and better hygiene.

Vikan tools are hygienically designed, which makes them easier to clean and less likely to harbor bacteria.

Vikan tools come in up to twelve colours, making them ideal for integration with colour-coded plans. Colour-coding helps prevent cross-contamination between raw and finished products, as well as keeping allergens separated.

Regardless of your operation’s size and complexity, Vikan has the tools and expertise to help you execute your colour-coding plans.

Source:

https://www.vikan.com/int/sectors/food-beverage-processing/dairy-processing