Particle Size Analysis for Alumina Powder

Measurement of Dispersion Quality of Submicron Alumina Powder in Water

The reality

Alumina (Al2O3) is an important ceramic material for industrial applications. The numerous fields of application range from construction materials, to filling materials, as well as abrasives and catalysts. In plants and mechanical engineering, alumina ceramics are mainly used for wear and corrosion protection. The particle size distribution largely determines the application range and the quality of an alumina powder. Reliably identifying the differences in particle size is therefore an essential requirement of the measuring instrument.

The submicron particles of aluminium oxide must often be reprocessed as a suspension in order to incorporate them in a bid to optimally improve the product’s properties. The challenge here is to produce stable dispersions. Agglomerates may affect the functionality of the product.

The photon cross-correlation spectroscopy (PCCS) means the analysis results are independent of the particle concentration. It allows measurements of the dispersion quality to be made, even in highly concentrated suspensions. The strengths of NANOPHOX are in the broad concentration range, in the sensitive resolution of bimodal particle distributions and in the sensitive response to changes in size.

The solution

Recommended Sympatec Particle Size Analyzer configuration

Dynamic Light Scattering sensor NANOPHOX CS 0.5 - 10,000 nanometer

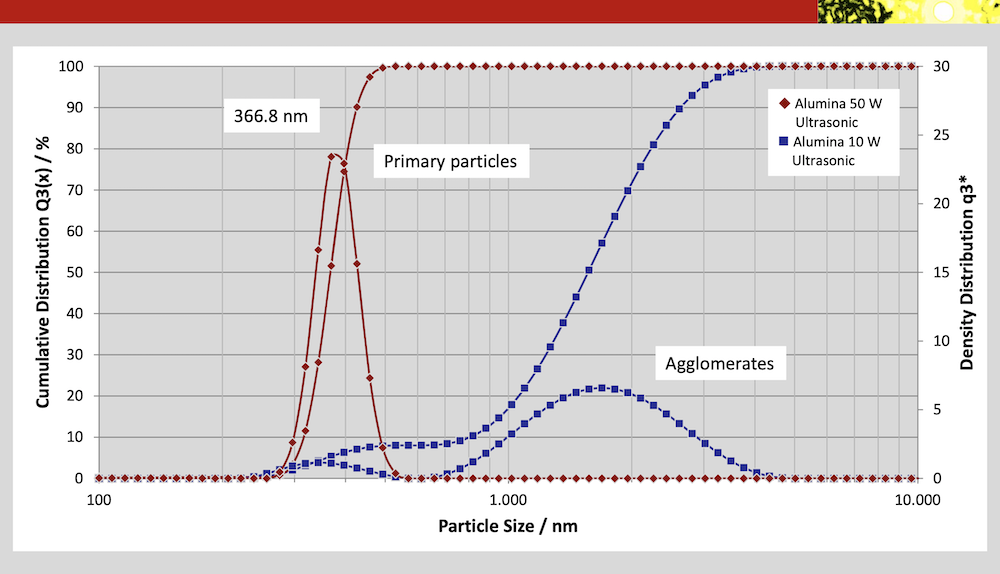

Measuring the dispersion quality Al2O3 suspension | 50 W ultrasonic power ensures good particle separation and a monodisperse product | 10W ultrasonic power exhibits inferior dispersion quality and a significant proportion of coarse agglomerates

The benefits

- Particle size distribution is vital for utilisation, processing and quality of alumina

- Reliable measurement of aluminum oxide as a powder and suspension

- Early identification of the formation of agglomerates

- Direct measurement of stabilisation kinetics in turbid dispersions

The Sympatec NANOPHOX CS is a highly effective tool for measuring particle size distribution, offering significant advantages in determining the application range and quality of alumina powder in manufacturing plants. By utilizing Photon Cross-Correlation Spectroscopy (PCCS), it provides precise and reliable measurements of nanoparticles in suspensions, ensuring consistent quality control. This accuracy is essential for optimizing the performance of alumina in various applications, such as ceramics, coatings, and electronics, where particle size influences properties like surface area, reactivity, and sintering behavior. The ability of NANOPHOX CS to detect even the smallest agglomerates enables manufacturers to identify inconsistencies and adjust processing parameters, leading to improved product uniformity and efficiency. Additionally, its real-time measurement capability reduces downtime, enhances production efficiency, and minimizes material waste.

By integrating NANOPHOX CS into quality control processes, manufacturing plants can ensure high-performance alumina powders, reduce variability, and maintain a competitive edge in industries that demand precision-engineered materials.

Source: