Particle size analyzer

The pioneer in Dry Dispersing

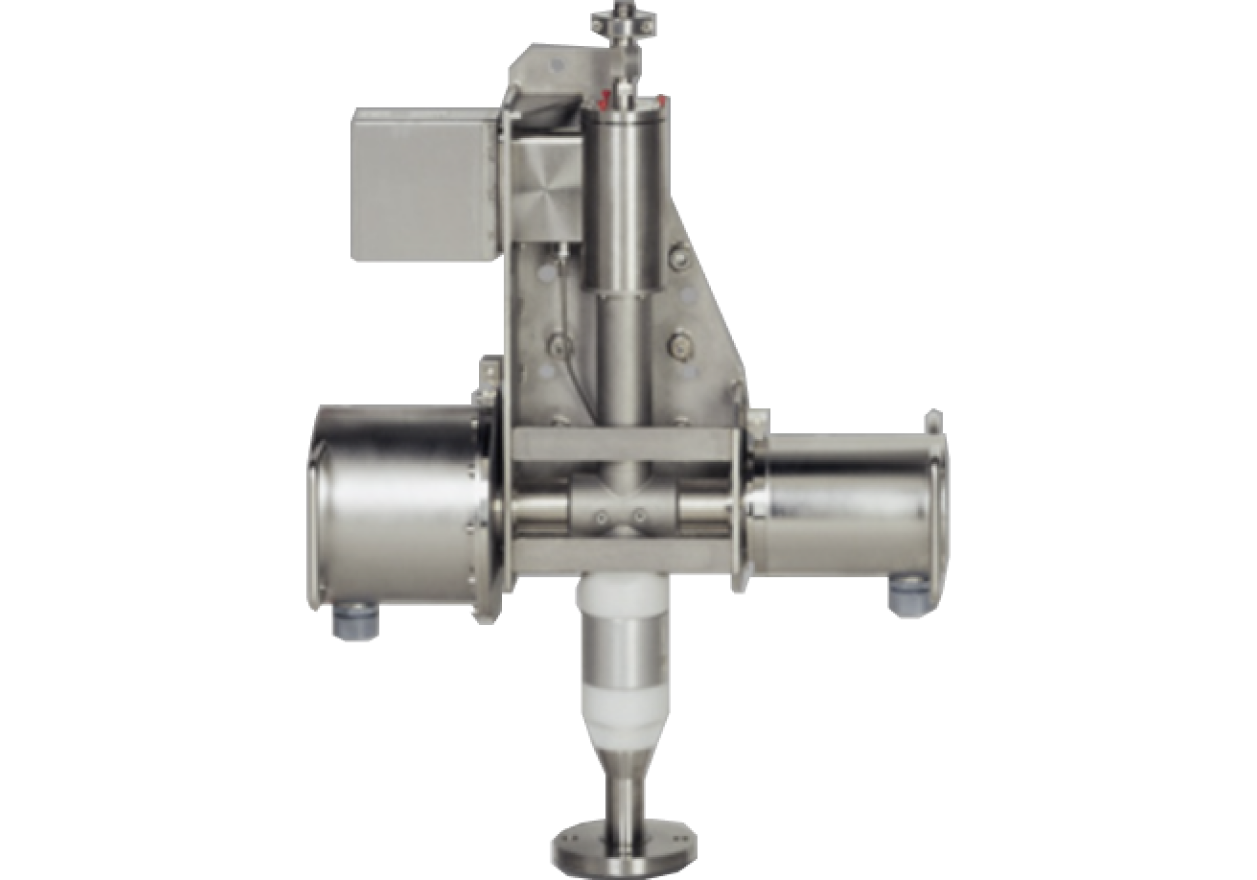

RODOS is the original by the inventor of dry dispersion. With this breakthrough innovation, Sympatec has opened up dry applications to particle measurement technology – as early as 1982. Since then, it has been possible to dry measure powders, fibers and granules in a manner appropriate to the product, with both laser diffraction and dynamic image analysis. No other method of dispersing is anywhere near as powerful or achieves such an efficient as well as gentle dispersion from the sub-micron to millimeter range. The speed, reproducibility, comparability and (above all) the high statistical reliability with large sample volumes up to more than 1,000 ml are particularly striking. However, even the smallest particle quantities in the microgram range are fully recorded with sophisticated trigger algorithms.

The dispersion effects in the RODOS injection disperser are caused by a special flow control in the long, straight dispersing line that ultimately enables a release of the isolated and highly accelerated particles in an aerosol jet. The product is fed in the axis of flow and initiates linear acceleration and mixing of particles with the compressed air or an inert gas. The dispersion energy is precisely adjusted to the product via the pre-pressure and an annular gap. The high air flow, the expansion and the ultimate jet formation provide a high exit speed of up to 100 m/s and an optimum optical dilution of the aerosol cloud for analysis. This way it is also possible to supply the sensor with difficult-to-disperse particles, such as residually moist, oily or magnetic powder, as perfectly dispersed individual particles without the risk of reagglomeration.

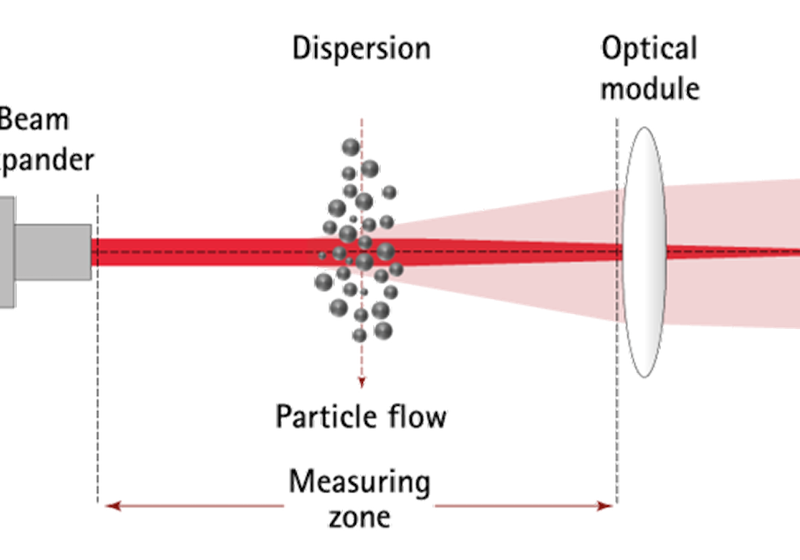

Laser diffraction method

Within our laser diffraction systems the primary physical diffraction set-up is realised deploying a parallel laser beam. This yields the purest optical alignment for analysis of extended special arrangements of particle collectives which allows for size characterization beyond limiting assumptions and constraint.

Following the premise of Fraunhofer diffraction scattered light of absorbing particles is measured under low angles in forward direction only. In contrast to Mie theory only the Fraunhofer model does not require knowledge of optical properties. Hence, solely Fraunhofer is applicable to mixtures of different materials and shapes. With laser diffraction the determined particle size always refers to the equivalent diameter of a sphere sharing the same diffraction pattern.

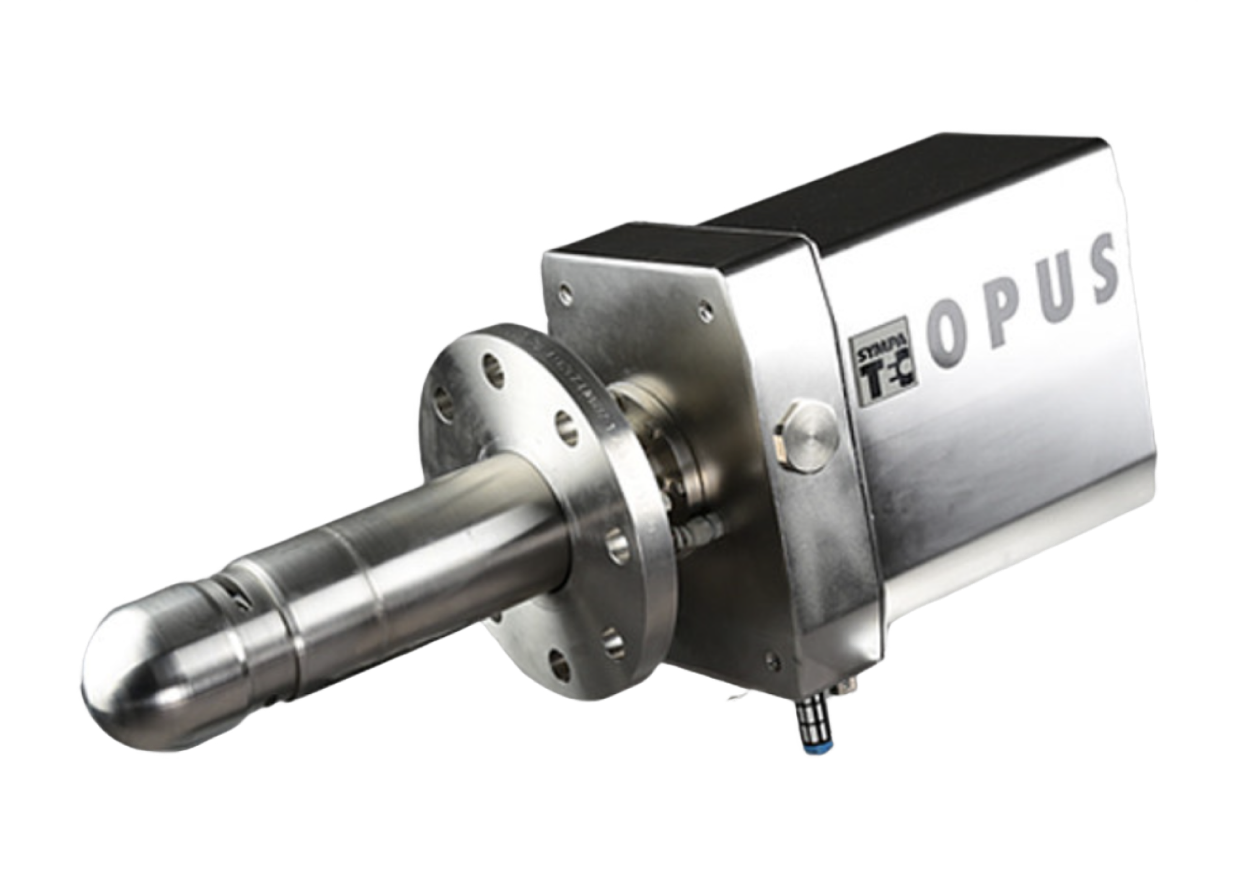

Within the past twenty years laser diffraction has become the dominating technique in particle sizing. In earlier days off-line particle size analysers have been adapted by sampler couplers to process pipes. Today you will also find the MYTOS family with in-line, on-line and at-line laser diffraction systems in our instruments portfolio especially adapted to the process.