Vikan cleaning tools for Chilled Ready-To-Eat Foods manufacturing plant

Chilled Ready-to-eat (RTE) food production is one of the most challenging in the food industry, particularly in relation to microbial control.

With microbiological expertise and extensive range of control options, let Vikan help you put the ‘chill’ back into your chilled food production. Chilled Ready-To-Eat (RTE) foods are foods that will not be cooked or reheated before serving. They include salads (containing fruit, vegetables, beans, sprouts, pulses, grains, egg, pasta etc.), cooked and cured meats, smoked fish, sushi, chilled desserts, sandwiches, cheese, and food that has been cooked in advance to serve cold. All require the highest standards of hygienic production to ensure maximum shelf-life and consumer safety.

Chilled RTE foods are also susceptible to rapid microbial spoilage. Consequently, strict hygiene control, of both the production environment and the food production equipment, is essential to maximise consumer safety and product shelf-life.

Selecting the right cleaning tools

General

- Most chilled RTE food productions sites will be thoroughly wet cleaned at the end of the production day.

- During production use cleaning equipment and methods that minimise the spread of contamination to open food and food contacts, e.g., use a bucket of water and a brush rather than a high-pressure hose.

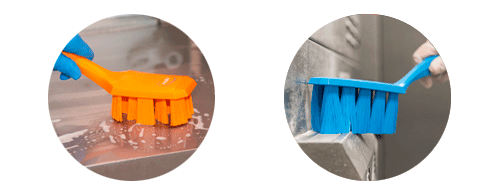

Brushware

- Select brushware of good hygienic design (easy to clean and disinfect) and frequently clean and disinfect them to minimise the risk of biofilm formation, and cross-contamination of microbes, allergens, and food ingredients.

- Select brushware with excellent bristle retention, to minimise foreign body contamination of your product.

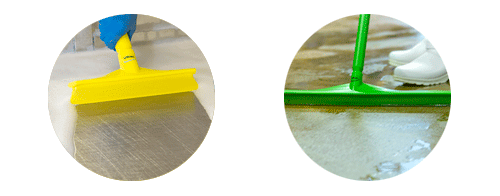

Squeegees

- A fully moulded, single-bladed squeegee is a great for removing liquids from surfaces and can be a good alternative to a brush for the removal of particulate debris. They have the added advantage of not clogging and being quicker and easier to clean and disinfect.

- Hand-held versions work well for cleaning food contact surfaces.

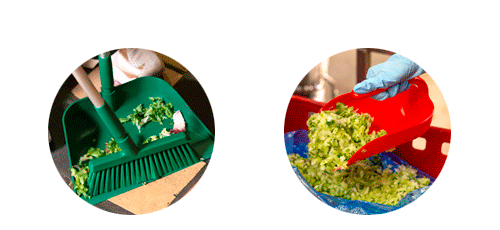

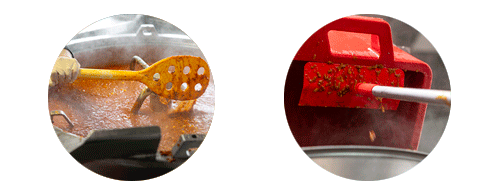

Colour-coded segregation

Use colour-coding to segregate areas and equipment and minimise the risk of cross-contamination. For example;

- Designate the low-risk areas as Green, and the High-risk area as Red.

- Use Brown cleaning equipment for non-food contact surfaces and blue for food contact.

- Use purple cleaning and food handling tools exclusively for use with a controlled allergen.

Product handling tools

Shovels, scoops, jugs, stirrers, and buckets should be hygienically designed, made of food contact compliant materials, and preferably be of a contrasting colour to the food to aid visual detection in the food.

Suggested Products for Chilled Ready-To-Eat Food manufacturing plants

Chilled RTE Product Processing requires strict adherence to sanitation rules and regulations. Tools from Vikan are made out of tough, compliant materials such as polypropylene and stainless steel. Unlike foamed plastic or wooden tools, Vikan high-quality products have smooth surfaces for easy clean-up and better hygiene. Our tools are hygienically designed, which makes them easier to clean and less likely to harbor bacteria.

Vikan tools come in up to twelve colours, making them ideal for integration with colour-coded plans. Colour-coding helps prevent cross-contamination between raw and finished products, as well as keeping allergens separated.

Regardless of your operation’s size and complexity, Vikan has the tools and expertise to help you execute your colour-coding plans.

Source:

https://www.vikan.com/int/sectors/food-beverage-processing/chilled-ready-to-eat-processing